News

-

Linear Cutter Stapler

The handle body includes a handle body, a push knife, a nail magazine seat and a nail abutment seat. The handle body is provided with a push button for controlling the push knife. The handle body is rotatably connected with a cam, and ...Views -

What's the advantages of surgical stapler ?

Compared with traditional manual suture, instrument suture has the following advantages:1. The operation is simple and convenient, saving operation time.2. One-time use to avoid cross-infection.3. Use titanium nails or stainless steel na...Views -

What's the Stapler

The stapler is the first stapler in the world and has been used for gastrointestinal anastomosis for nearly a century. It was not until 1978 that the tubular stapler was widely used in gastrointestinal surgery. Generally divided into on...Views -

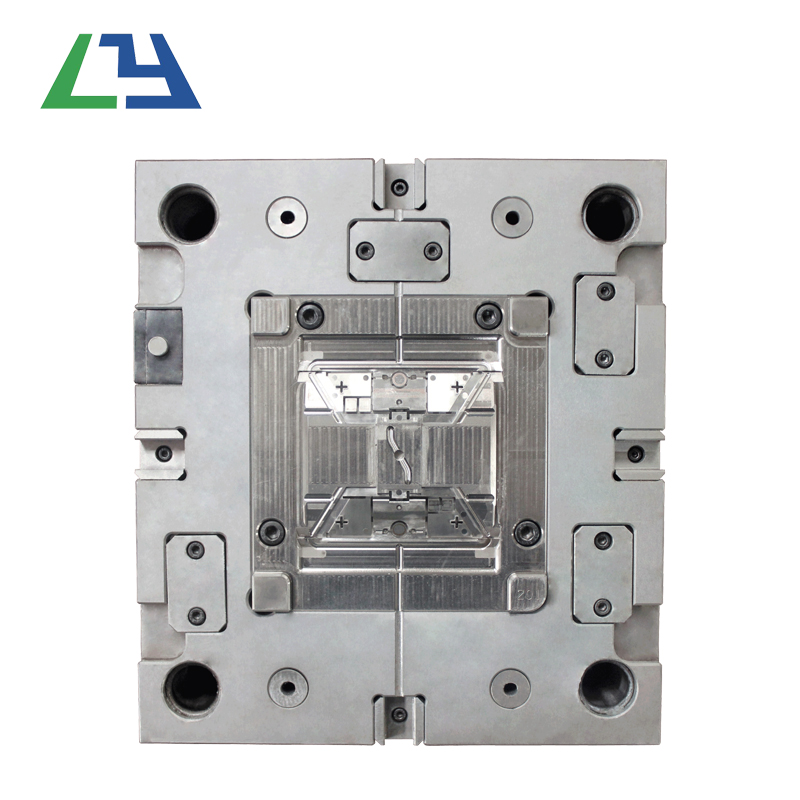

Why plastic products have burrs?

1. The clamping force is too low: the clamping force of the injection machine is too low to keep the template of the forming process tightly closed, and burrs will occur. Adjust the clamping force of the template.2. Mold has gaps: If the...Views -

How to increase the brightness of injection molded products from the process and mold?

Injection mold1. If the mold cavity is poorly processed, such as scars, micro-holes, abrasion, roughness, etc., it will inevitably reflect on the plastic parts and make the plastic parts poorly shiny. For this, the mold must be carefully...Views -

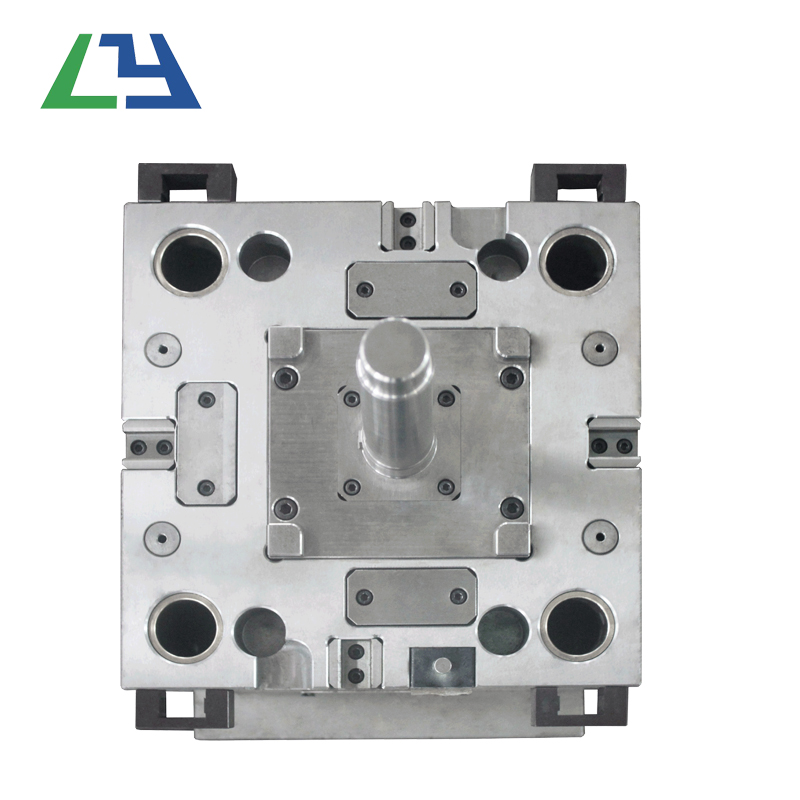

What are the plastic mold materials?

The most important factors of mold materials are thermal strength and thermal stability. Commonly used materials: mold materials,working temperature, forming materials, mold materials>1000℃ Nickel alloy, copper-based alloy mold, hard a...Views -

What types of plastic ?

Classification of plastics:1. According to the different properties of the plastic after being heated, it is divided into thermoplastic plastics and thermosetting plastics.The molecular structure of thermoplastics is a linear structure, ...Views -

Overview and forecast of engineering plastic products in July

In July 2020, the engineering plastics market was mixed. Mainly due to the epidemic and rising temperatures, the downstream start-up load has decreased, and demand has been slow to follow up. However, some products are supported by upst...Views -

What are the main raw materials of plastic products?

The plastic raw material is a polymer, which can also be called a macromolecule or a macromolecule, and is also commonly known as a plastic or resin. The so-called plastic raw material is actually one of the [synthetic resins]. Its shap...Views -

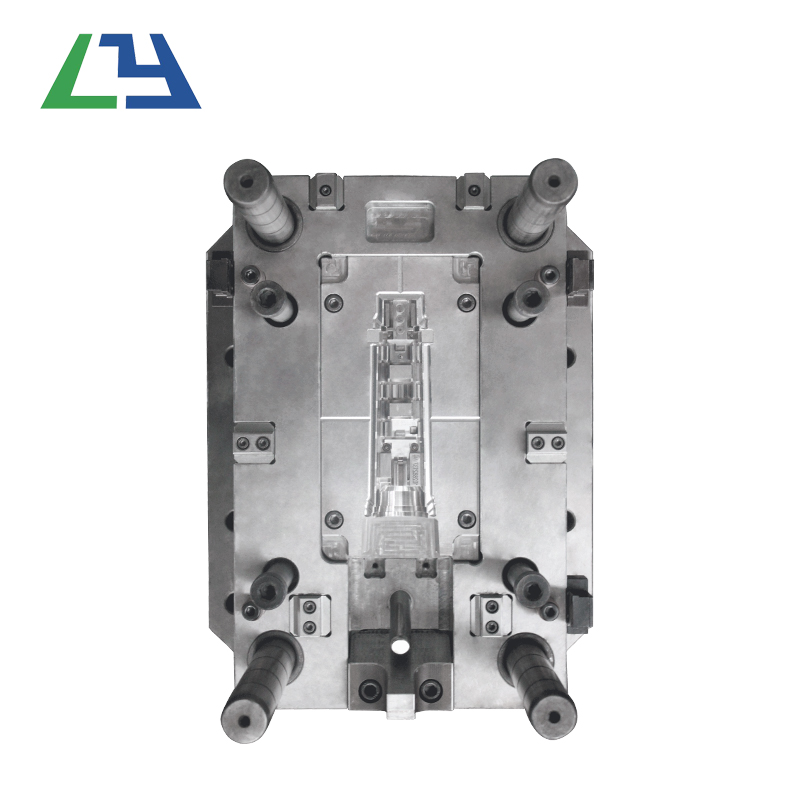

Inection molding

Injection molding is a method of producing shapes for industrial products. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding compression method and...Views -

The development trend of plastic mold processing technology

With the continuous development of my country's plastic mold processing industry, plastic mold processing technology has also been continuously improved. These advances have completely changed the traditional mold design and manufa...Views -

News of the plastic mold industry

From the analysis of the development prospects of China's plastic mold industry, we understand that plastic mold manufacturers should focus on the development of large, precise, complex, and long-life molds with high technology con...Views