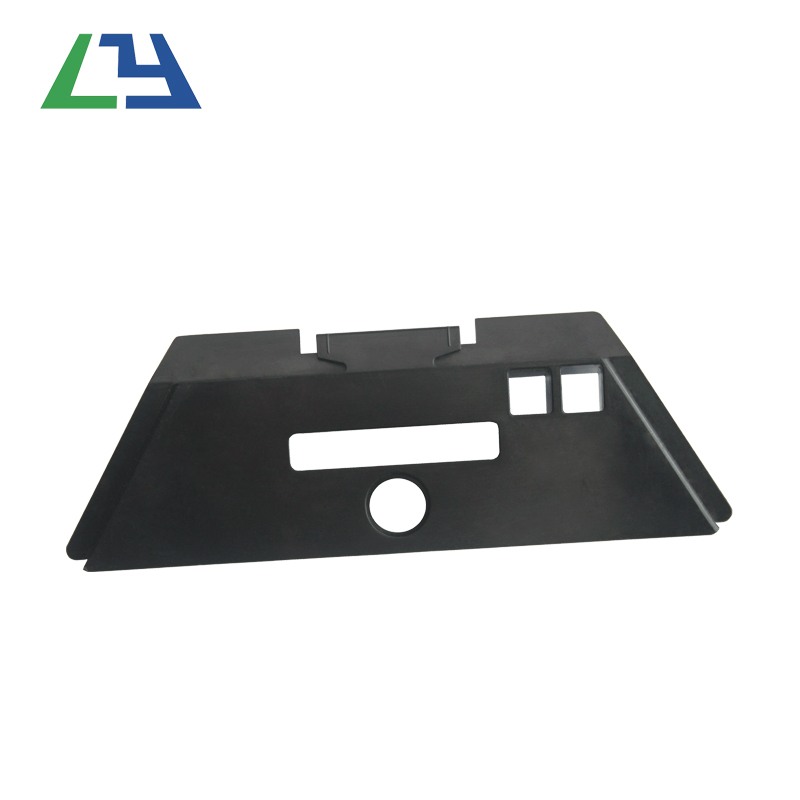

Plastic injection mold auto car shell parts

Five Advantages Of Products

- OEM/ODM service

- Experienced engineer

- Strictly QC system

- 24 hours production(two shifts)

- Prompt delivery

Product Details

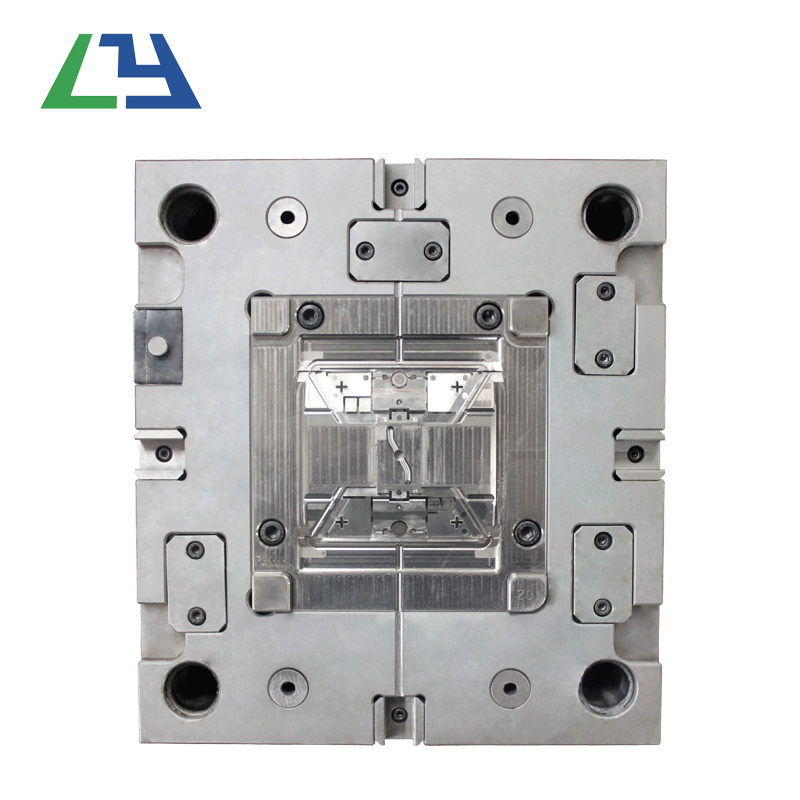

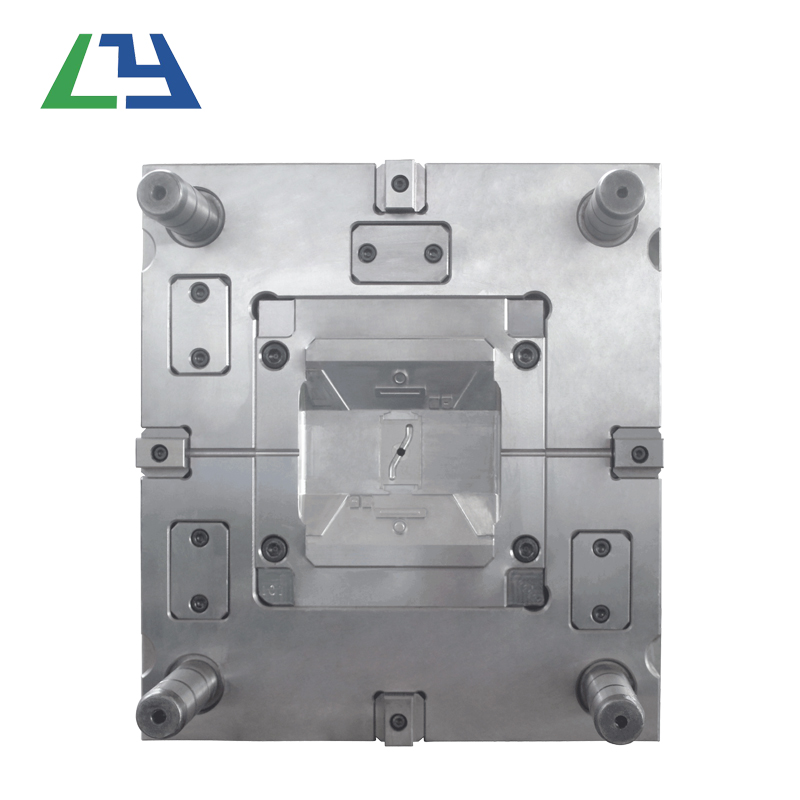

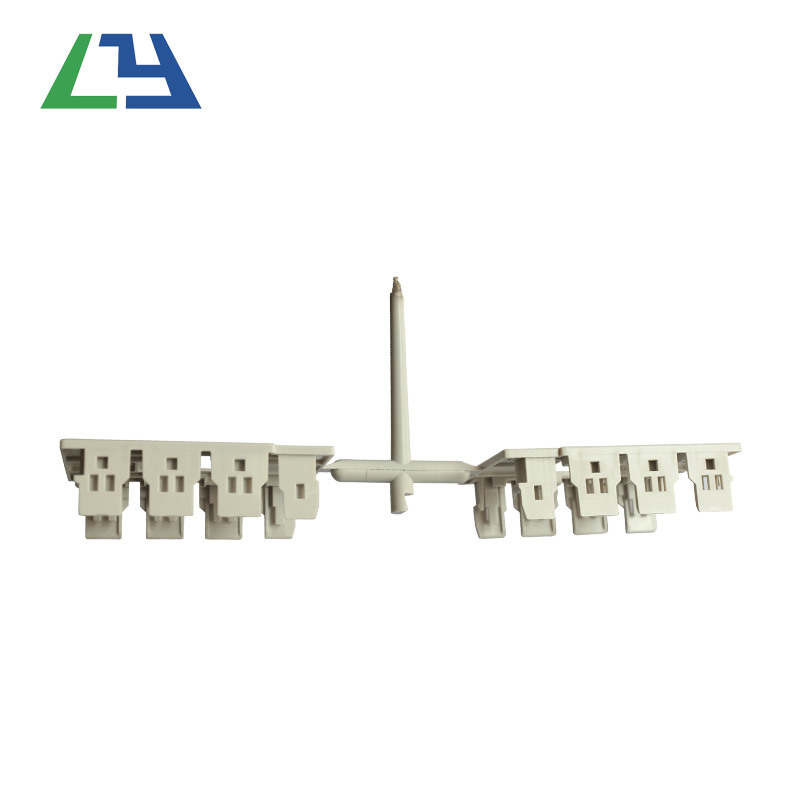

Plastic injection mold auto car shell parts

Product Description:

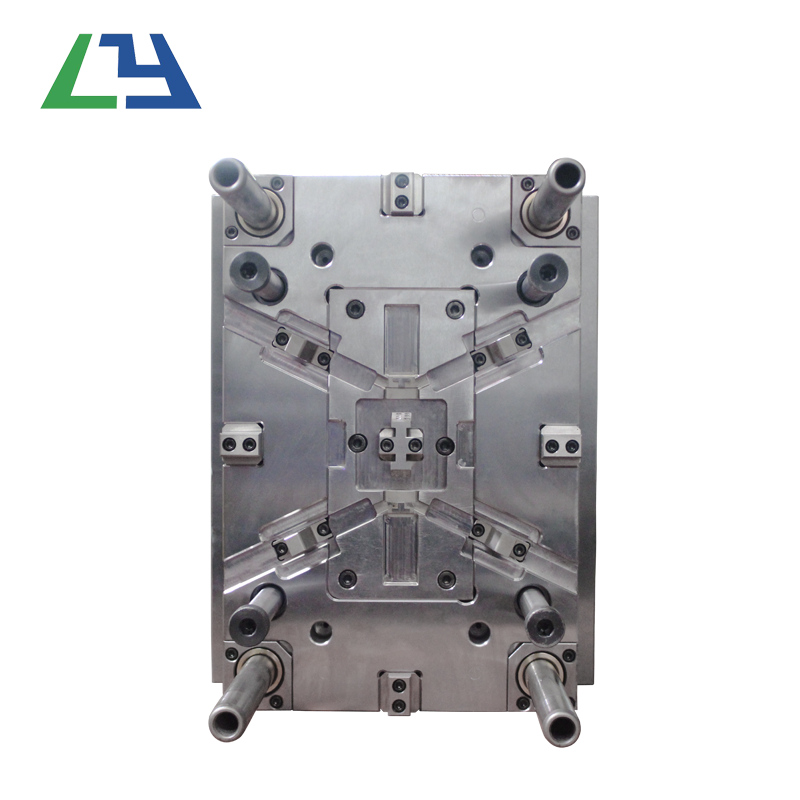

Mold tolerance can do from ±0.005 to ±0.01mm

Low speed wire cutter process tolerance: ±0.005mm

CNC process tolerance:±0.01mm

Grinding process tolerance: within ±0.002-0.005mm

EDM process tolerance: ±0.01mm

FOT time: around 4 weeks

Mold standard: FUTABA,LKM,HASCO,DME

Use Meusburger and MISUMI brand components

Steel brand: ASSAB and SCHMOLZ+ BICKENBACH

Hot runner: Synventive,Mold master,Yudo,Hasco

Use in: Automotive,Household appliance,Medical product,Daily necessities,Consumer Electronics,Industrial product etc.

Our Service:

1. 10 years of rich experience in mold industry and a wide range of products

2. Main markets covers USA, Europe, Asia

3. Outstanding merchandise and considerate 24 hours on-line customer service

4. Punctual delivery, good quality and satisfy customers request

5. Best after-sale service

6. A number large production lines, strong technical strength and advantage production equipment

Our Company:

Suzhou Leyang Technology factory majors in manufacturing of plastic injection mold ,plastic parts etc. Our main market :USA, Europe, Japan, Malaysia ,Singapore .We have over ten years of experience in manufacturing, quality control and good customer service to our customers. The biggest strength is that we have our own tooling and mold dept., for which we can wholly control the cost and lead time of product molds, then make more new shapes and cost-effective products to our customers. Under this situation, the new product cycle and cost are relatively superior to other suppliers in the market.

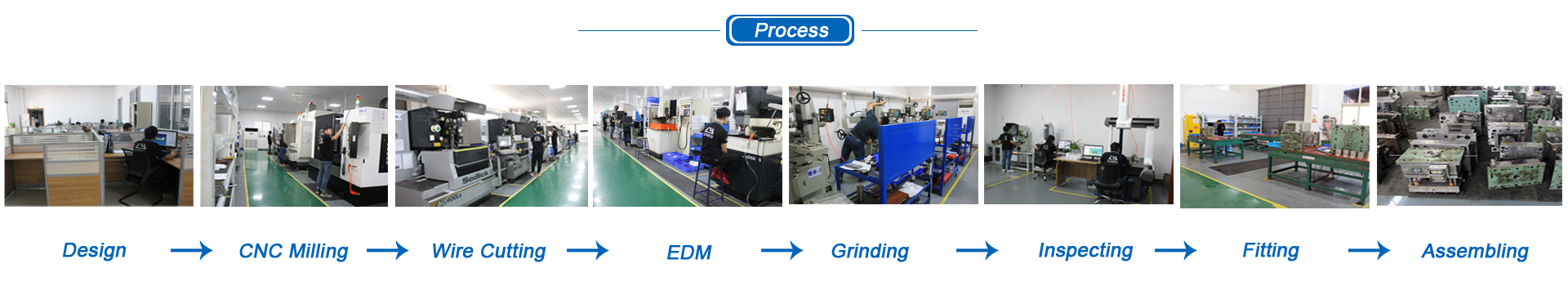

Tooling Developing Procedure:

1. Quotation: We need your require clearly

2. Negotiation: Material, cavity, price, delivery time, payment term, etc.

3. Order: According your own design or choice our design

4. DFMEA: Deign failure mold & Effect analysis to reduce risk

5. Mold design: 2D/3D drawing

6. Cutting Tooling Notice: After customer approve the mould design will start making mould

7. Weekly Report: We will update the mold schedule every week

8. Sample Confirm: Send you sample for conform it, if not satisfied by customer. We modify mould.

9. Delivery Mold: Delivery mould after customer approve sample and arrange shipment

Suzhou Leyang Technology Co.,Ltd.

Contact Person: Sophia Xiao

Department: International Market

Post: Sals Manager

Telephone: +86 13926068023

Landline: +86 0512-66385718-8016

Company Address: No.5368,Wuzhong Avenue,Xukou Town,Suzhou City,Jiangsu Province

Website: www.leyang.tech

Previous: Plastic Box Injection Mold

-

Plastic Injection Moulding Exporter

-

Plastic injection mould china

-

Plastic injection molding companies

-

Plastic injection mold auto car shell parts

-

Plastic Box Injection Mold

-

Plastic injection pvc fitting mould making factory

-

Custom Designed Plastic Precision Injection Mold

-

Plastic Injection Molding for Plastic Parts